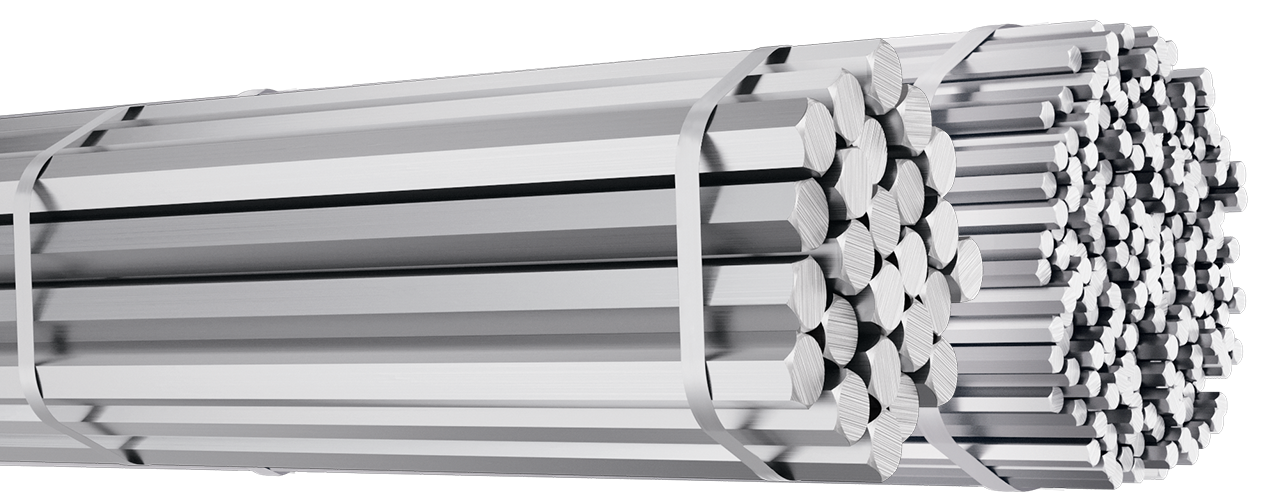

From the success of RodaExaFit®, on the drawing processes for hexagonal profiles,

Rodacciai has developed a new even more performing product Roda ExaFit EVO®.

The Roda ExaFit EVO® process allows to drastically reduce the defects not detectable by standard

controls, allowing to obtain material with a maximum defect depth equal to 1% of the diameter, and a maximum

percentage of material with defects above the limit equal to 0.2% of the weight of the supply.

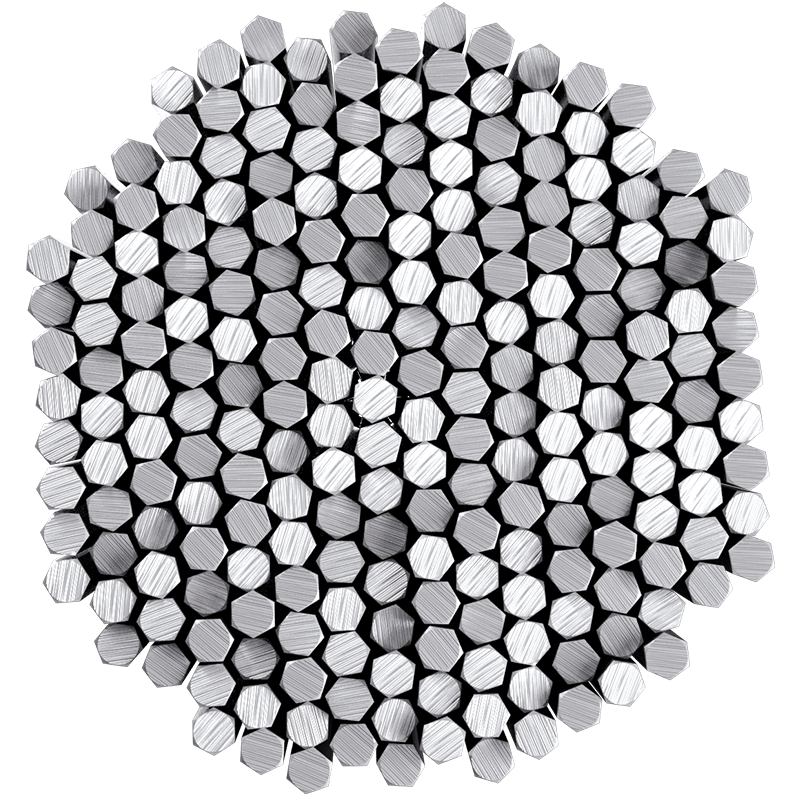

Steel Family - Profiles - Size Range

| Hexagonal | Free Cutting Steel | Stainless Steel |

|---|---|---|

| Cold-Drawn | 22 - 46* * Bars max. 3 metres |

|

Maximum defect depth equal to 1% of the diameter and a maximum percentage of material with defects exceeding

the limit equal to 0,2% of the weight of the supply.

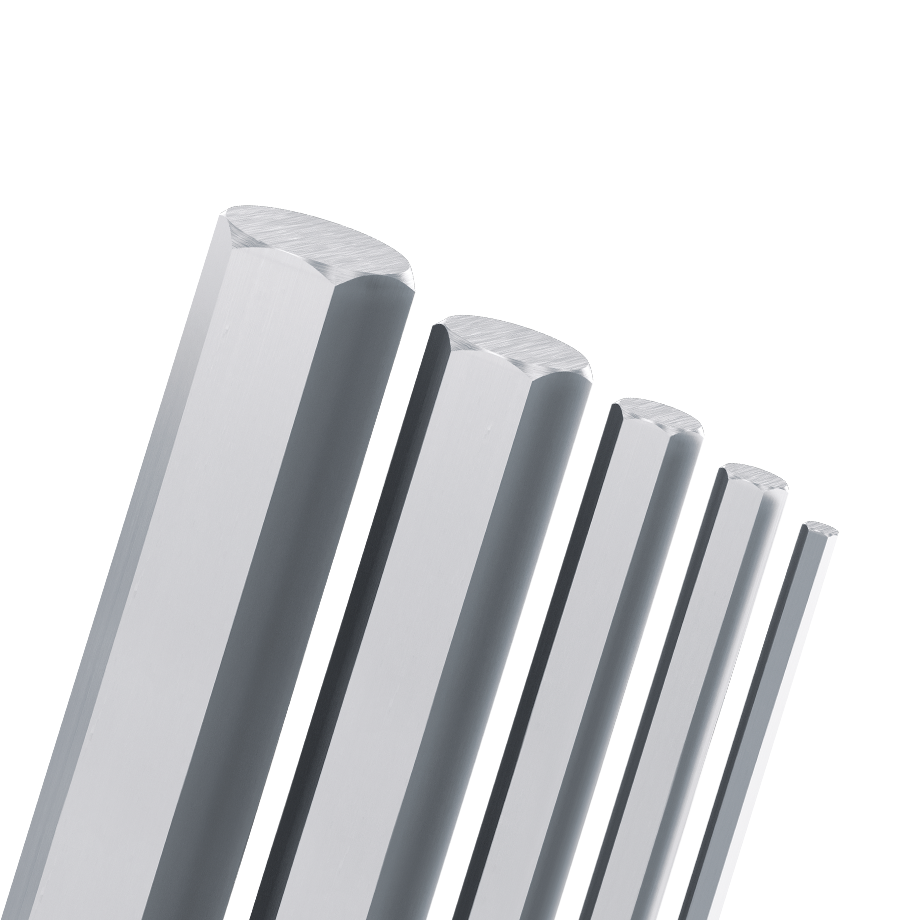

The steel bar manufactured according to the Roda

ExaFit EVO® process will have one end coloured, which must be cut by the customer because not

checked.

The other end will be guaranteed to be checked and perfectly in tolerance, allowing the customer to manufacture the beginning of the bar without having to head it.

0,2%

Maximum guaranteed percentage with discontinuity above the level set by EN 10277:2018